CNC Turn-Milling Machines

HAMUEL HSTM SERIES

High Speed CNC Turn-Milling Machines

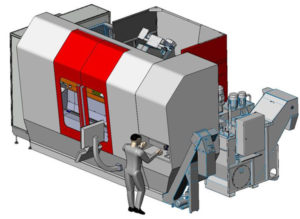

The HSTM series consists of CNC turn-milling machines with a horizontal work piece orientation. The HSTM series provides cost effective CNC manufacturing of high precision work pieces such as turbine blades, blisks and impellers.

The series also handles:

Single-part and series production

Other turn milled parts with a high contour complexity

Work pieces up to 1400mm long with maximum diameters of 560mm

The HSTM series is based on a horizontal machining center. The entire unit is tilted forward by 45° for optimized weight distribution and visibility of the work piece. With a surface quality of up to Ra=0,8 μm, the Hamuel HSTM Series meets the highest standards of modern blade manufacturing technology. Cutting edge drive and control technology guarantees high productivity and flexibility; the rigidity of the HSTM series allows accurate high speed cutting.

The machine is built as a single machine body, with all components optimized for milling of work pieces in a horizontal orientation – especially turbine blades. Rotary axes with standard interfaces provide the highest productivity in precision machining.

Installation

The compact design of the machine allows a quick and trouble-free installation without any special requirements.

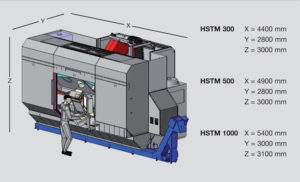

The HSTM Series is available in three machine sizes:

HSTM 300

HSTM 500

HSTM 1000

The modular concept allows for easy customizing to meet the specifications of your machining process.

Blisks up to 850mm diameter can be machined with a simple variation to the machine’s base

Work pieces can be loaded from the front top or side

Fully integrates with automatic loading systems

Milling Spindle

The motor-milling spindle allows for machining of a wide variety of materials. High spindle speeds for aluminum and high spindle power with slower spindle speed for Titanium are available in the same Motor Spindle.

Cooling and lubrication systems are integrated with outer cooling, high pressure, and minimum quantity lubrication through the spindle or outside of the spindle. An exhaustion system for cleaning the cabin air is also available.

Schedule a Demo with the Hamuel HSTM HD

Learn how Hamuel can improve your machining process

The Hamuel HSTM is available for demos in our Middleton technical center. Call INIRAM at 978-854-3037 to schedule a demo for your CNC milling and turning application.